Sintered Nd-Fe-B, as the strongest permanent magnets discovered up to now, is preferred by permanent magnetic devices, due to its highly cost-effective performance based on rich rare-earth resources, manufacture in large scale and technology development.

Ⅰ Sintered Nd-Fe-B magnets are popular for their merits as follows:

1.High energy product,commonly referred to as maximum value (BH) max. Sintered Nd-Fe-B magnets have high magnetic energy per unit volume, which makes it possible for modern permanent magnetic devices to become smaller and lighter and, therefore, cost greatly reduced.

2. Great intrinsic coercive force, denoted as Hcj. Since Hcj is easy to reach up to 12 kOe, magnets applied in high demagnetizing field could be designed thin enough to keep devices compact.

3. Demagnetization curve with good rectangularity. Magnetic polarization strength is almost invariable in a wild range of demagnetizing field. Shown in rectangular coordinates, the B-H demagnetization curve is a straight line in the second quadrant and extending to the third quadrant. That means, in a magnetic circuit, polarization strength isin constant. Accordingly, magnetic circuit design work is simplified and development cycle of new permanent magnetic devices is greatly shortened.

4,Low flux leakage. On the one hand, sintered Nd-Fe-B magnets have an extremely high anisotropy field and, flux lines, thereby, are confined to the two pole faces, resulting in a low leakage. On the other hand, the great intrinsic coercive force permits magnets of a small dimension in the magnetization direction and naturally reducing the flux leakage. To save time and cost for design and development of permanent magnetic devices, finite element method could be used to simulate magnetic circuit and calculate the exact field.

5,High energy efficiency. Thanks to the good rectangularity of demagnetization curve, recoil permeability denoted as rec could be lower than 1.2, while the lower rec is, the better magnet flux get back to original magnetic state.,

6,Low eddy current loss. Sintered Nd-Fe-B magnets have higher resistivity than Sm-Co magnets, let alone ordinary metallic materials. In alternating magnetic field such as that in electric motors, magnets have lower eddy current loss, and therefore devices work with less heat and lower temperature rise.

Ⅱ There are some key points in search of good sintered Nd-Fe-B magnets:

1. Grade

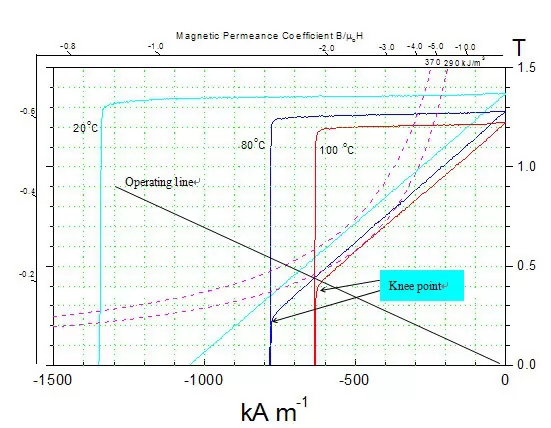

The operating point of a permanent magnet should be higher above the knee point Bk, Hk at the highest working temperature. In another word, the maximum reverse applied field (self-demagnetizing field included) denoted as Hr and the apparent flux density Bd should meet the following inequality:

Bk, Hk refer to flux density and magnetic field at knee point.

As the picture shows, Bk=0.2 T at 80C and Bk=0.4 T at 100C. Then Bd needs to be >0.2 T at 80C and >0.4 T at 100C, or at 100C, B-H curve should cross the operating line at a point where Bd>0.4 T. Otherwise an irreversible demagnetization will occur at the high temperature.

For this reason, we should determine the highest working temperature of magnets before selecting grade. From the picture, we find both magnetic remanence and coercive force decrease as the temperature rises, thus the knee point goes up. Since the operating line of a magnet is determined once circuit structure is designed, what we need to do, in fact, is to find the minimum coercive fore.

B-H curves of different grades are available. Feel free to contact us for details.

2. Dimension

Sintered Nd-Fe-B magnets are brittle materials with significant surface effect, so generally we suggest the dimension is above 1.0 mm. But do not hesitate to contact us for special solution.

Residual internal stress always exists in sintered Nd-Fe-B magnets for its brittleness. So magnets need to be chamfered to prevent edge chips.

3. Surface treatment

Sintered Nd-Fe-B magnets are sensitive to the environment and surface treatment is usually required. We provide various metallic and non-metallic coatings to prevent corrosion, the major cause of field failure except for high temperature.